Breaking the Mold

We trace the story of Ray and Charles Eames’s partnership and problem-solving back to an almost magical handmade plywood-molding device called “Kazam!”

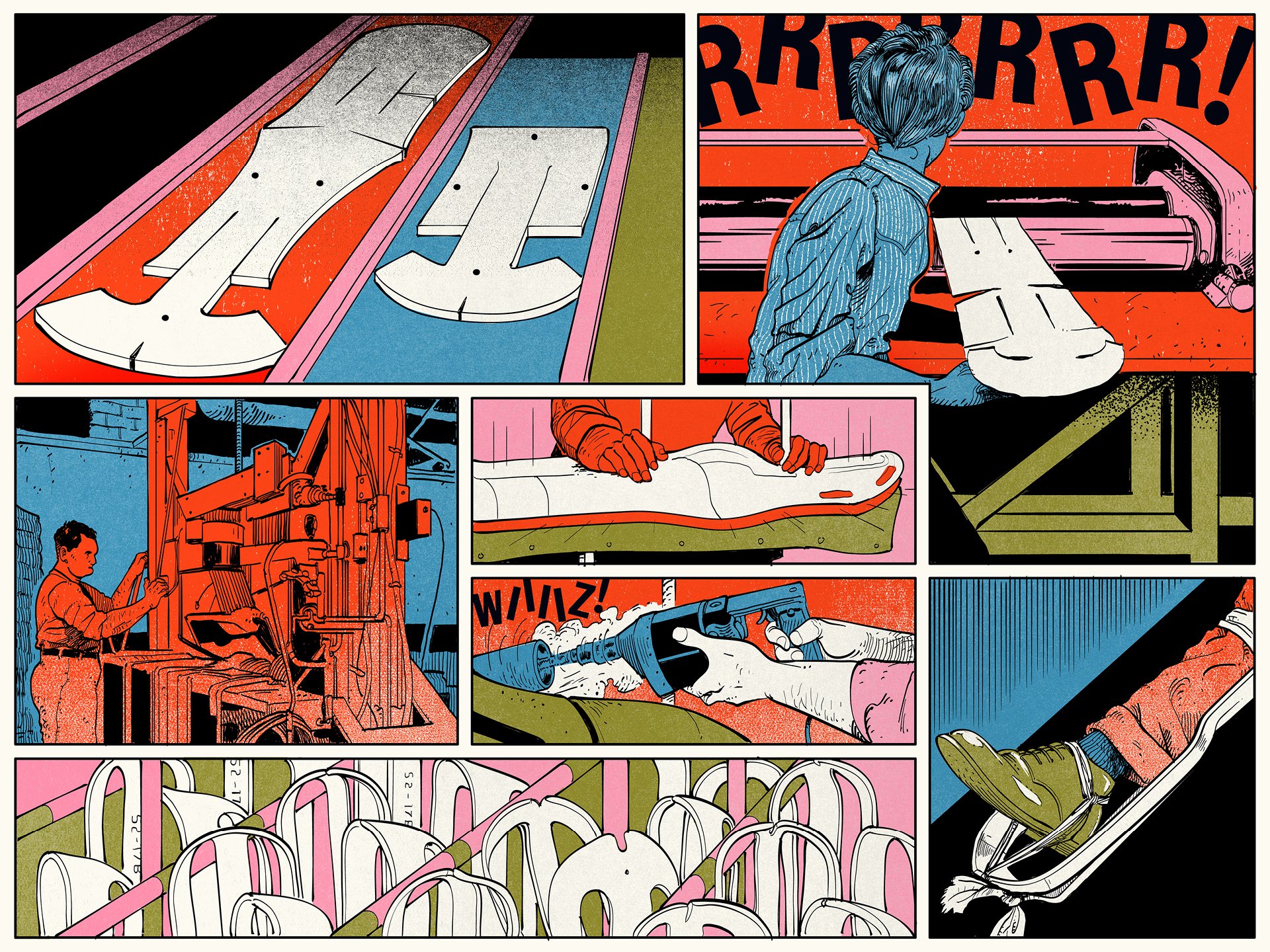

It was Ray Eames, with her typical flair, who nicknamed the machine Kazam! after the sorcerer’s incantation alakazam, because it could form bent plywood “like magic.” This couldn’t have been farther from the truth. The Kazam! made complex curves out of flat planes through hard work—physical, mental, electrical—as Ray and Charles Eames never gave up on the idea that plywood could bend in multiple directions to better cradle the human body and harness industrial innovation in service of value. The Kazam! and the bestselling series of chairs that were its eventual commercial offspring serve as an ideal illustration of the practical magic the Eameses and their collaborators brought to a task. Those chairs also underline the many humble handmade and hand-finished attempts required to produce the seemingly hands-free designs that have become modern pin-ups. “The problem of designing anything is in a sense the problem of designing a tool,” the Eameses wrote in 1953. To make a mass-produced molded plywood chair, then, the key was to invent the tools to create the tool.

The first Kazam!, made in 1941, was a triangular box made of two-by-fours. The right-angled side held a plaster mold of a seat into which electrical coils were embedded (akin to radiant-heated concrete floors). The slanted side served as a lid, the two-by-fours spaced so that the tube of a bicycle pump could thread between the slats. To mold plywood, the Eameses would place a sheet of thin wood veneer in the machine, paint it with glue, and then repeat, five to eleven times, crisscrossing the grains to build strength. Once this sandwich was complete, they would close the machine and inflate a rubber membrane with the pump, pressing the veneer against the plaster surface, where the heating elements would slowly cure the glued layers into the desired shape. The process took four to six hours and so many amperes that Charles Eames had to climb the nearest power pole with an insulated cable so that they could get electricity direct from the source. Charles’s warning doodle (to “keep out of the Kazam!”), suggesting that danger lurked within, was likely directed at anyone who might interrupt the machine’s intensive process.

While Charles had designed site-specific furnishings for his earlier private architectural commissions, his interest in serial furniture production dates to his time at Cranbrook, where he found an ideal collaborator in fellow instructor Eero Saarinen. Influenced by European designers like Alvar Aalto and Marcel Breuer, who successfully demonstrated the ability of plywood to bend in two-dimensions, Charles and Eero co-produced plywood furnishings for Eero’s architectural collaborations with his father Eliel Saarinen, including Kleinhans Music Hall (1940) in Buffalo, New York, and the Crow Island School (1940) in Winnetka, Illinois. For their entry to the Museum of Modern Art’s 1940 “Organic Design in Home Furnishings” competition, however, the pair set about pushing molded plywood into the next dimension.

Alongside a series of modular casegoods and tables, their MoMA entry included three single-piece, three-dimensionally molded plywood chairs: one with arms like penguin flippers and a large oval cut-out in the back; a curvy, high-backed lounge; and a simple scooped shell which presaged many of their ensuing designs. Ray Kaiser (later Ray Eames), then a Cranbrook student, helped make their multiple competition entries, while Don Albinson, another student, made such convincing miniature furniture models that the judges presumed the photographic proposals were life-sized. Despite input from engineers at Grand Rapids’s Haskelite, a maker of plywood, the designers were unable to get the smooth, seamless curves they wanted, and resorted to upholstery to camouflage the rough, handmade forms. Lesson learned: Design for the realities of manufacturing, not just the finished look.

The following year, Charles, now married to Ray, left Cranbrook for the West Coast and got a job at the art department for MGM. They moved into a two-bedroom apartment in architect Richard Neutra’s Strathmore Apartments: one for sleep, and the other for dreams. It was in this second bedroom that the couple assembled the Kazam! using wood scraps and hardware from the studio and began producing a series of chair seats that more closely resembled potato chips—albeit potato chips with a keyhole cut-out that enabled the bentwood pieces to come together to form a seat back. Once released from the machine, the edges of the seats were trimmed with a handsaw. Some of these prototypes include a metal fastener across the seam, an early indication that the connections between parts would be as important as the parts themselves.

The problem of designing anything is in a sense the problem of designing a tool.

Ray and Charles Eames, 1953

As they worked on the plywood seats, the Eameses contended with their limited space, limited income, and wartime materials shortages. In 1942, a partnership with Arts & Architecture editor John Entenza allowed them to set up a workshop outside their apartment, and for Charles to quit his day job. They couldn’t fully capitalize on the lessons learned from the Kazam! until they adapted that knowledge to military use, in the form of the plywood leg splints commissioned by the Navy. (For Ray and Charles, it was important that they were able to contribute to the war effort in a way that saved lives rather than ending them.) A 1946 patent under Charles Eames’s name shows both the splint—a complicated piece that had to be lightweight and stackable, able to support the natural curve of the human leg, and punctured with holes to strap it on—and the more sophisticated version of the Kazam! required to produce them.

The Eameses also began to hire staff, including Gregory Ain, Harry Bertoia, Herbert Matter, and Griswold Raetze. Ain, an architect who had already designed offices for the U.S. Plywood Corporation, as well as a Plywood Panel System for house building, was given the title chief engineer, and worked with Charles to perfect the tools required. Ray later told Ralph Caplan that Charles, Ain, and Raetze all worked on the problem of “the force needed to keep the plywood in place” in the new, larger molding machines. “It was the important factor to keep everything from being blown up.” Period photos of their 10946 Santa Monica Boulevard studio show a variety of sizes of Kazam!s for different uses, including splints, pilot seats, and airplane nose cones. By 1943, they sought further capital investment, and the Plyformed Wood Company became a division of Evans Products Company, eventually producing 150,000 splints.

Simultaneous with the work for the Navy, Ray Eames (with Charles undoubtedly at the Kazam!) continued her exploration at the axis of industry and artistry, and created a series of gestural bent plywood sculptures. The biomorphic expression she honed is reflected in the chairs they eventually brought to mass production with Evans and eventually Herman Miller. Between “Organic Design” and the Kazam! and the nose cones and the sculpture and, finally, success, there were tens of unnamed and unremembered seats, each one adding some bit of hard-won knowledge. Charles later described the process as “a 30-year-flash.” The first result was the DCM, or Dining Chair Metal, which split the wood back and seat into two curved parts, elegantly linked by stainless steel tubes and sitting atop four spindly legs. “In the design of any structure,” they wrote, “it is often the connection[s] that provide the key to the solution.”

When the DCM was exhibited at MoMA in 1946, it was as part of a series of domestic vignettes which included wire-legged tables, the low-slung LCW, or Lounge Chair Wood, and storage pieces, all labeled “New Furniture Designed by Charles Eames.” It was not a showcase for a chair but for a whole new lightweight, indoor-outdoor way of life—like the one the Eameses would pioneer at their own house a few years later. The press release mentioned Charles’s previous plywood collaboration with Saarinen but stated that “Eames...continued on his own to explore the unsolved problems.” A House & Garden article covering the exhibit mentioned, at least, that it was a “one-man-and-his-wife” show.

V&A curator Christopher Wilk writes in the 2017 catalog Plywood: A Material Story, “It is not hyperbole to claim that the DCM became the most influential and imitated chair of the mid-twentieth century.” British designer Robin Day said that “every designer I knew had a picture of the Eames chair pinned to their drawing board,” while American designer Edward Wormley joked that it would lead to “a mass of mosquitoes posing as tables, chairs, and carts.”

To prove that bent ply could stand up to daily wear, this initial showcase included a giant revolving drum in which a DCW (Dining Chair Wood) loudly tumbled. The idea of a chair rattling in an industrial barrel, frozen today in a stroboscopic image by Matter, is delightful. It brings the patched-together, let’s-try-this-again, now-we-need-more-power process by which the Eameses figured out how to form three-dimensionally molded plywood in their bedroom into the hushed and polished halls of MoMA. You can call that magic, sure, but isn’t it actually more inspirational to admit that even the most beguiling spells require untold effort and trial and error before they get cast? ❤

At Kazam! Magazine we believe design has the power to change the world. Our stories feature people, projects, and ideas that are shaping a better tomorrow.